1:10 Turbofan Engine - Teching (build review)- EngineDIY & Model Ship World

1:10 Turbofan Engine

Teching

Catalogue #33ED3479934

Available from EngineDIY for $849.99USD (minus discount)

A turbofan or fanjet is a type of air-breathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of the preceding generation engine technology of the turbojet, and a reference to the additional fan stage added. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

Animation of a 2-spool, high-bypass turbofan

A. Low-pressure spool

B. High-pressure spool

C. Stationary components

1. Nacelle

2. Fan

3. Low-pressure compressor

4. High-pressure compressor

5. Combustion chamber

6. High-pressure turbine

7. Low-pressure turbine

8. Core nozzle

9. Fan nozzle

The turbofan was invented to improve the fuel consumption of the turbojet. It achieves this by pushing more air, thus increasing the mass and lowering the speed of the propelling jet compared to that of the turbojet. This is done mechanically by adding a ducted fan rather than using viscous forces by adding an ejector, as first envisaged by Whittle.

(Information abridged from Wikipedia)

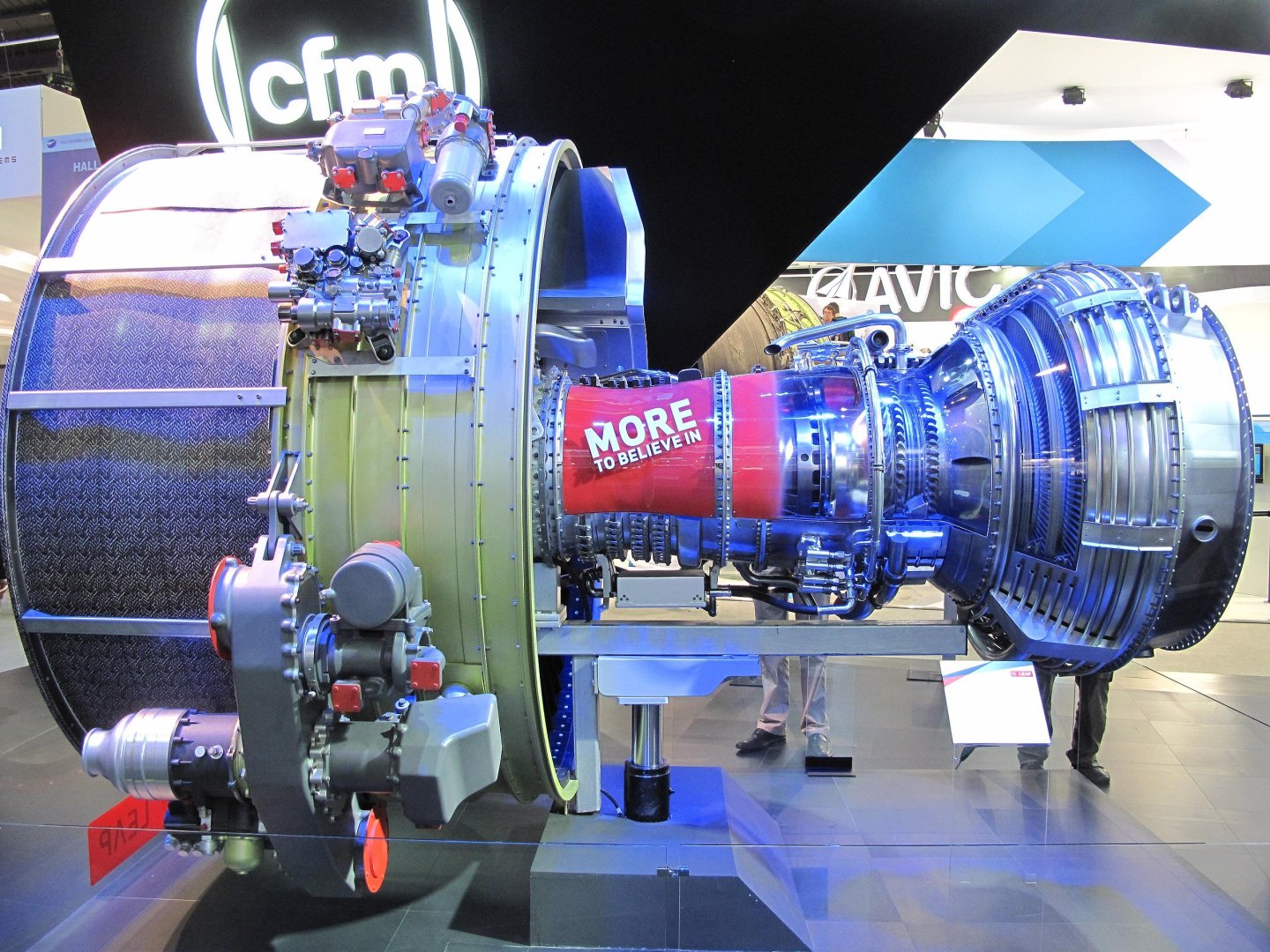

The kit

This is a large and heavy kit. It's also very expensive and I make no secret of this. The box with contents, weighs in at about 5kg, and the completed model at around 4kg. In all, there's over 1000 parts, including the various fittings of course. That product box is extremely sturdy and takes a real effort to get that lid from the base. You can get an idea of the size of this kit with my magnifying visor sat on top. The engine seems to be based on the CFM International LEAP turbofan engine, as fitted to the Boeing 737 MAX and Airbus A320 Neo. The finished model also features a test stand and a throttle unit with full engine sound.

Here are a few more specs, supplied by Teching.

Material: Aluminum alloy + Stainless Steel

Model: Dual Rotor Turbofan Engine

Scale: 1/10

Model Length: 380mm

Fan Diameter: 165mm

Number of Parts: 1000+PCS (Components: 400+PCS, Screws & Nuts: 600+PCS)

Drive System: Motor-driven

Battery: 3.7V 800mAh Lithium Battery

Power Charging Cable: DC 5V USB Cable

Charging Time: 3 hours

Battery Life: 1 hour (at Full Charge)

Assembly Time: Approx. 10 hours

Underneath that heavy lid are several trays of parts, all numbered so you know exactly where to find the parts you need. A number of parts are fairly similar, so it's important you use the correct ones as you go. On top of the parts trays is a clear acetate sheet to make sure nothing comes loose, and lastly, the colour instruction manual is provided.

Here you can see just how those parts are supplied. Many smaller parts, such as stator blades etc. are packed into clear wallets and then sat within their numbered recesses. One point to note here is that there is a little fine, slightly powdery debris on many parts, from that foam. I found that blowing the parts with an aerosol cleaner helped first...especially as the construction is precision.

Tray 1

Tray 2

Tray 3

and read more here....

Conclusion

You really have to like assembling mechanical models to get the most from this kit. There are LOTS of nuts and bolts to tackle and you'll need a reasonable bench area to store the various subassemblies as the build commences. The model is all metal in construction (apart from the clear viewing panels) and is something that really should not be rushed, and why would you want to if you are paying a premium for such a project. Tools are supplied with the kit, although my 1.5mm hex driver head did shear off and I continued with my Wera hex head set for most things. This is very much a precision kit and the excellent instructions need to be followed at each step. There are more than enough images for you to get orientation correct, and the text is very easy to follow, with no ambiguity. The only thing I would suggest is that you get a little model grease for the various gears, and a little lube oil for the bearings. The kit does have a space in the accessories box for that lube, but it's not included in the UK shippings, for reasons I don't know. If you've ever wanted to buy a model engine of a turbofan, then it gets no better than this one.

So what do I think of the kit in terms of build-ability? Well, we'll look at this over the next posts I make, culminating in a full build and video test startup.

My sincere thanks to Lucas at EngineDIY for the opportunity to build this remarkable kit on Model Ship World. To buy directly, click the link at the top of this article.

To get a nice fat discount on this kit, use the voucher code JAMESHATCH at checkout.

Comments

Leave a comment